The patient is at the heart of everything we do.

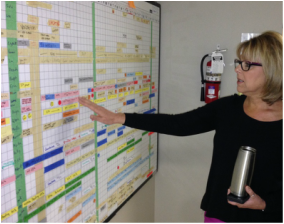

Since 1995, JBA has worked together with our clients to transform the patient experience.

JBA can help you deliver:

• Higher-quality care • Compassionate service • Greater reliability • Improved patient access • At a lower cost |

|

Leading transformation at Virginia Mason

In 2001, Virginia Mason Medical Center in Seattle, Washington, became one of the first hospitals to transform its entire management system using the Toyota Production System. Building on the pioneering work with PeaceHealth, JBA helped Virginia Mason turn an ailing healthcare system into one of the top hospitals in the world. Quality of patient care, safety, cost efficiency, and staff morale were all significantly improved. As a result, during the recession from 2007 to 2008, many hospitals shut down services and cut back on staffing while Virginia Mason prospered. In 2010, nine years after its adoption of Lean, Virginia Mason was awarded Hospital of the Decade by the Leapfrog Group. By then, the world had begun to take notice, and other healthcare leaders have begun to adopt Lean and the Toyota Production System. |

Guiding a host of recognized Lean

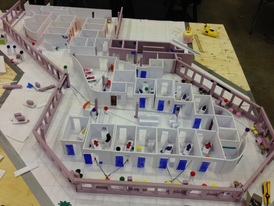

healthcare leaders Since its work with Virginia Mason, JBA has advised key leading healthcare organizations in how to best transform their management systems to achieve truly astounding results. In 2011, the Canadian province of Saskatchewan began a massive Lean healthcare journey with JBA. This effort, involving more than 40,000 healthcare workers in hundreds of facilities and offices province-wide, represents the largest healthcare transformation so far in the world. After several years of intense implementation and hundreds of Lean events, the province's Ministry of Health has announced:

JBA has helped set Saskatchewan on the path to healthcare transformation. Now, JBA's Lean experts are ready to help your organization achieve equally impressive results. |

NEW EDITION!

|

The Toyota Way to Healthcare Excellence Increase Efficiency and Improve Quality with Lean John Black with David Miller and Joni Sensel Special Discount Code: TOYOTA |

|

©2015 John Black and Associates