Dr. Deming and Dr. Juran transformed manufacturing in the United States. Each rose from poor beginnings to become cornerstone leaders of the quality control movement.

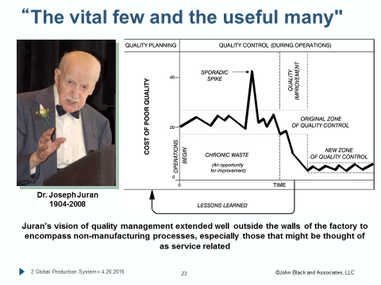

Dr. Joseph Juran

Joseph Juran, a child immigrant from Romania, worked his way up the ladder at the Western Electric Company, formerly a division of AT&T. Juran invented the Pareto principle, which states that 80 percent of waste comes from 20 percent of procedures.

For decades, Juran helped U.S. manufacturers cut waste and deliver better products. Now, we apply our learnings from Dr. Juran across all sectors of business. Here’s a video of Steve Jobs when he was president at Next, on working with Dr. Juran:

For decades, Juran helped U.S. manufacturers cut waste and deliver better products. Now, we apply our learnings from Dr. Juran across all sectors of business. Here’s a video of Steve Jobs when he was president at Next, on working with Dr. Juran:

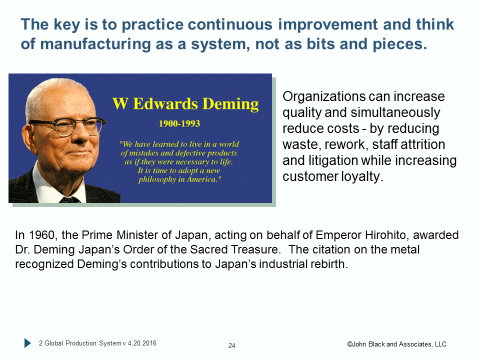

Dr. W. Edwards Deming

Dr. Deming spent most of his childhood on a barren farm in Cody, Wyoming. His family lived on the bare minimum to survive. He went on to study engineering and eventually earned his doctorate in physics.

Deming began his transformative work in Japan. He pioneered the use of applied statistics in the factories, and production soared. In 1960 he was awarded the Awarded the Second Order Medal of the Sacred Treasure by the Emperor of Japan for his service in saving the economy of the wore-torn nation from desolation.

After teaching all over the world, he returned to the United States. My wife, Joanne, was one of Dr. Deming’s protégés before we met. In addition to playing an instrumental role in Boeing’s Lean implementation during the late 1980s, she had the rare opportunity to shadow W. Edwards Deming during his consultations with Ford, General Motors, Chrysler, and Harvard. She also assisted him at some of his seminars.

Deming began his transformative work in Japan. He pioneered the use of applied statistics in the factories, and production soared. In 1960 he was awarded the Awarded the Second Order Medal of the Sacred Treasure by the Emperor of Japan for his service in saving the economy of the wore-torn nation from desolation.

After teaching all over the world, he returned to the United States. My wife, Joanne, was one of Dr. Deming’s protégés before we met. In addition to playing an instrumental role in Boeing’s Lean implementation during the late 1980s, she had the rare opportunity to shadow W. Edwards Deming during his consultations with Ford, General Motors, Chrysler, and Harvard. She also assisted him at some of his seminars.

Deming taught the world that systems are responsible for waste, and way get rid of waste is through continuous improvement. As Deming said, “The timid and the fainthearted, and the people who expect quick results, are doomed to disappointment.”

At JBA, Dr. Deming has taught us to look critically at every tiny part of the hospital care process. When we find problems, we then act step by step to reclaim wasted time and supplies.

When I was handed the responsibility to start a quality revolution at Boeing in the mid 1980s all Boeing senior leaders were required to attend the Juran and Deming seminars. In addition we formed a Quality Improvement Center that was staffed with the best and brightest executive potential candidates representing all Boeing functions. They also attended Juran and Deming and other specialized training.

Dr. Deming also taught us the importance of getting upper level management on board before a transformation. Ultimately, as Deming says, management is responsible for the system. To get sustainable results, management has to be committed to the long haul of continuous improvement.

At JBA, Dr. Deming has taught us to look critically at every tiny part of the hospital care process. When we find problems, we then act step by step to reclaim wasted time and supplies.

When I was handed the responsibility to start a quality revolution at Boeing in the mid 1980s all Boeing senior leaders were required to attend the Juran and Deming seminars. In addition we formed a Quality Improvement Center that was staffed with the best and brightest executive potential candidates representing all Boeing functions. They also attended Juran and Deming and other specialized training.

Dr. Deming also taught us the importance of getting upper level management on board before a transformation. Ultimately, as Deming says, management is responsible for the system. To get sustainable results, management has to be committed to the long haul of continuous improvement.

RSS Feed

RSS Feed