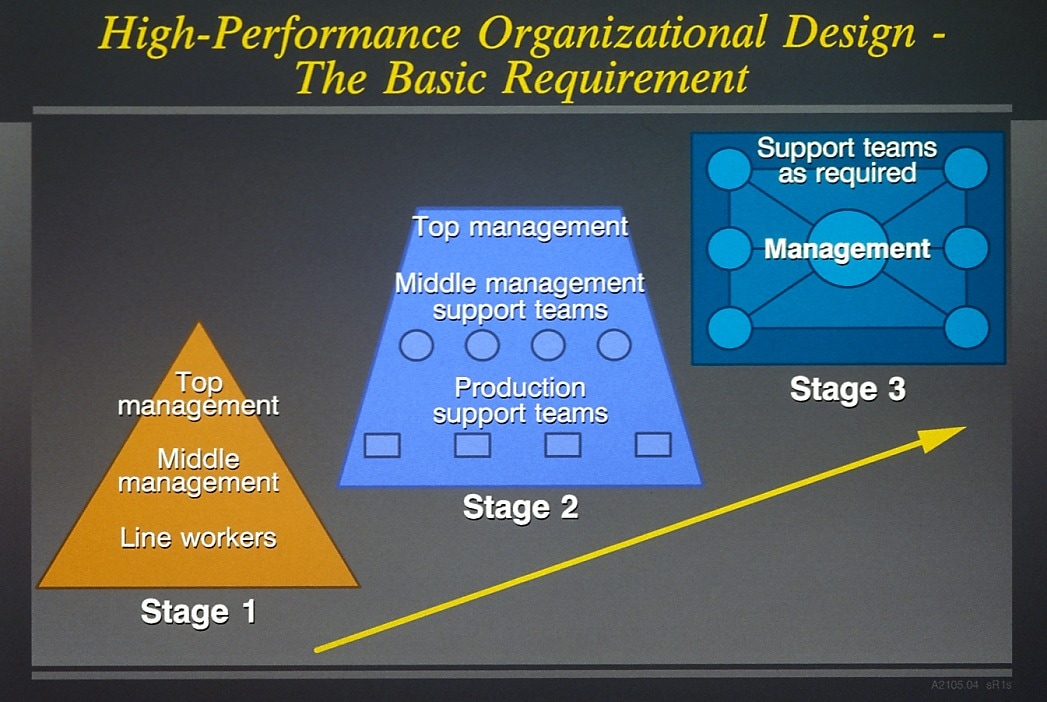

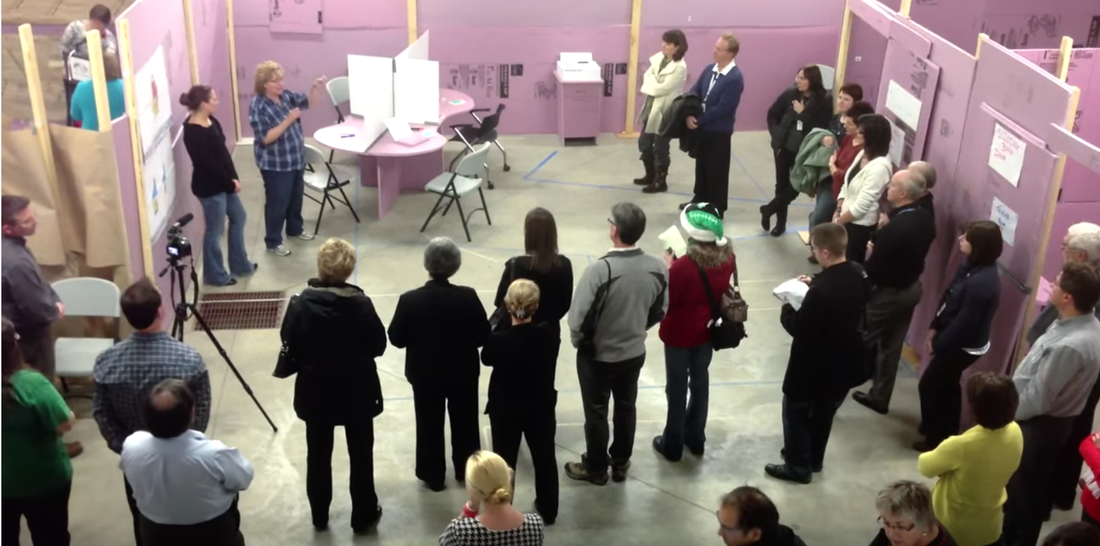

Fundamentally, Lean is about changing the paradigm of how organizations work. In traditional organizations, decisions are handed top-down, and lower-level staff have no say. In our hospitals, that means that deadly mistakes go unreported for the sake of following orders. Nurses and doctors are frustrated. Patients feel lost in the process. Lean gives us the tools to end this mismanagement.

Lean makes every employee, patient, and family member a valued part of the care process. Every person participates in quality control. The results? Better care, zero defects, and a richer bottom line.

But culture change is difficult. Any type of change, even if it’s good, meets resistance. People’s lives are on the line—no one wants to take chances. That’s why culture change requires bold leadership, a bold vision. Leaders must believe in their organization’s ability to deliver the highest quality of care. Leaders must work day and night to get everyone on board, to build new bridges between patients, care teams, and staff.

Lean makes every employee, patient, and family member a valued part of the care process. Every person participates in quality control. The results? Better care, zero defects, and a richer bottom line.

But culture change is difficult. Any type of change, even if it’s good, meets resistance. People’s lives are on the line—no one wants to take chances. That’s why culture change requires bold leadership, a bold vision. Leaders must believe in their organization’s ability to deliver the highest quality of care. Leaders must work day and night to get everyone on board, to build new bridges between patients, care teams, and staff.

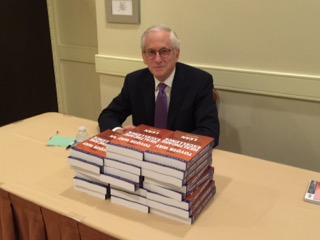

William Edwards Deming said it best:

“To successfully respond to the myriad of changes that shake the world, transformation into a new style of management is required. Then to take is what I call profound knowledge – knowledge for leadership of transformation.”

“To successfully respond to the myriad of changes that shake the world, transformation into a new style of management is required. Then to take is what I call profound knowledge – knowledge for leadership of transformation.”

“Our staff and physicians already felt they were focused on patients, but the structures and processes we used were largely provider-centric. We were often only giving lip service to listening and responding to what patients and families really wanted. In my organization, we had prepared the ground through our work on patient- and family-centred care, but even so, a Lean management system required far more courage.” |

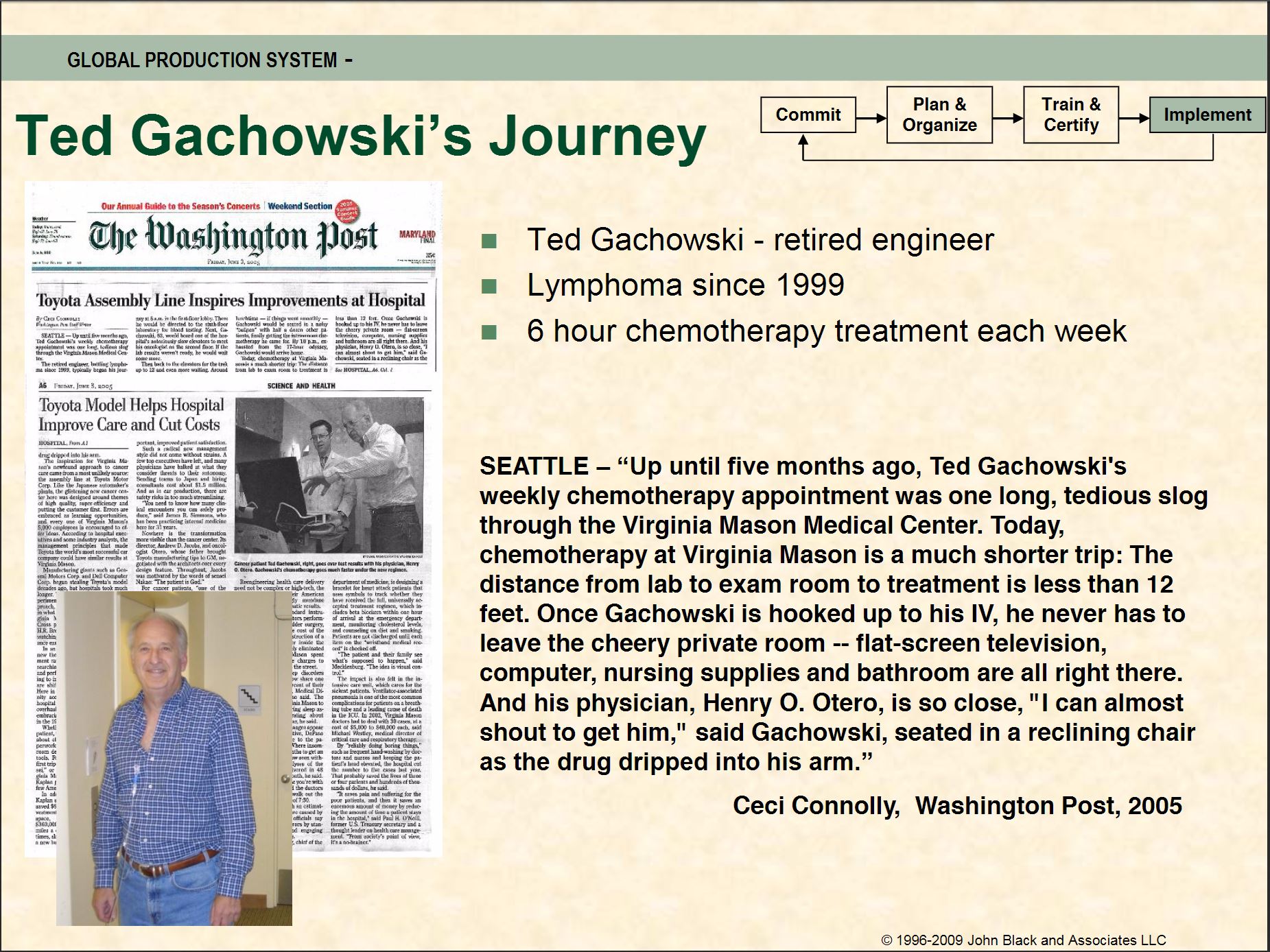

When healthcare CEOs and presidents take these courageous steps, transformation happens.

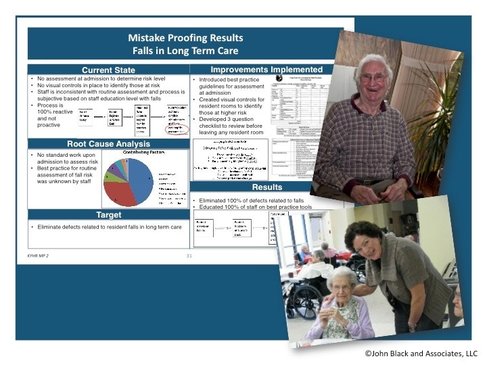

Fewer falls. More successful surgeries. Chemotherapy patients in and out faster, and back home to recover.

Changing the culture to be open to criticism at all levels is a huge shift. Yes, it’s difficult. But it saves lives.

RSS Feed

RSS Feed