Lean transitioned from manufacturing to healthcare through the vision of two pioneering women: Sister Monica Heeran and Joanne Poggetti.

Sister Monica Heeran, the CEO of PeaceHealth, had heard me speak in Chicago at a Juran Institute symposium on managing for quality in research and development. She asked for more information, because she wanted to improve PeaceHealth’s not-for-profit healthcare system in the Pacific Northwest. Probably the first US healthcare CEO to embrace Lean, she signed a two-year contract with Poggetti and me to lead a Lean implementation.

Back then implementing Lean in healthcare was a dream

Sister Monica Heeran, the CEO of PeaceHealth, had heard me speak in Chicago at a Juran Institute symposium on managing for quality in research and development. She asked for more information, because she wanted to improve PeaceHealth’s not-for-profit healthcare system in the Pacific Northwest. Probably the first US healthcare CEO to embrace Lean, she signed a two-year contract with Poggetti and me to lead a Lean implementation.

Back then implementing Lean in healthcare was a dream

Before Sister Monica signed the contract, I asked Joanne Poggetti, then president of Poggetti & Associates, what she thought. Without hesitation, Poggetti said yes, Lean could be done in healthcare. She had first-hand experience of inefficiencies and mistakes in healthcare. She had the vision to see how Lean could eliminate those mistakes.

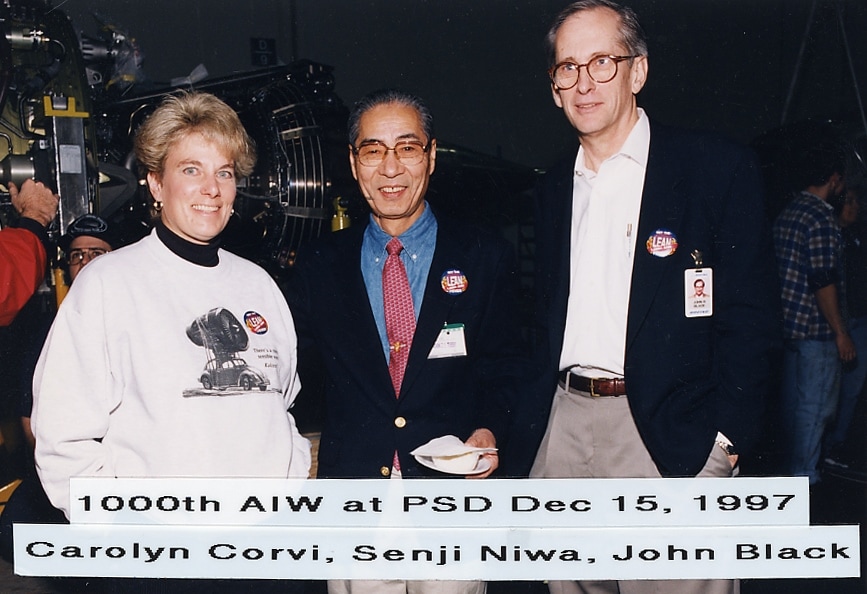

So in 1996, before it was fashionable, Sister Heeran had the courage to implement Lean in her hospital system. Poggetti took Sister Heeran and her CEO’s to Japan. Sister Heeran was the first healthcare CEO in the world to see Toyota in action in Japan.

So in 1996, before it was fashionable, Sister Heeran had the courage to implement Lean in her hospital system. Poggetti took Sister Heeran and her CEO’s to Japan. Sister Heeran was the first healthcare CEO in the world to see Toyota in action in Japan.

Poggetti and Sister Heeran came back and implemented learnings. Early results were outstanding.

- Lead times for billing cut from 28 to 3 days.

- Home Health services redesigned in a few weeks

- Saving $600k almost immediately

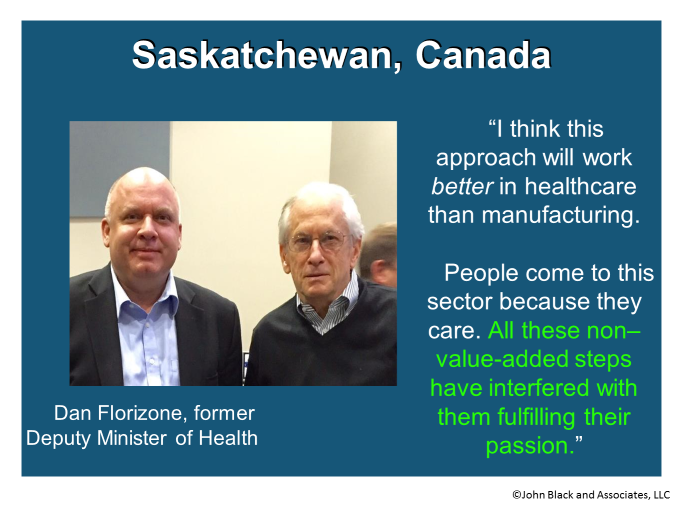

Sister Heeran later retired and Lean didn’t continue at PeaceHealth. But the ground was broken for Lean in healthcare. Now, hundreds of healthcare organizations have seen the transformational impact of Lean, all thanks to Joanne Poggetti’s vision and Sister Monica Heeran’s courage.

Later after joining Boeing, Poggetti became a protégé of Dr. Deming & traveled with him.

The best part? I was lucky enough to marry Joanne and we’ve continue the work she started.

Later after joining Boeing, Poggetti became a protégé of Dr. Deming & traveled with him.

The best part? I was lucky enough to marry Joanne and we’ve continue the work she started.

RSS Feed

RSS Feed