Last post, I talked about how world-class healthcare organizations focus on process. Before that, I talked about the importance of placing the patient at the center of that process. Today, I’m going to put that all together and talk about the end goal of any world-class healthcare facility: quality care.

In healthcare, your reason for being is quality care. To be a world-class healthcare organization, you must excel at deploying rapid, effective patient care.

Rapid quality care deployment begins with a sense of urgency.

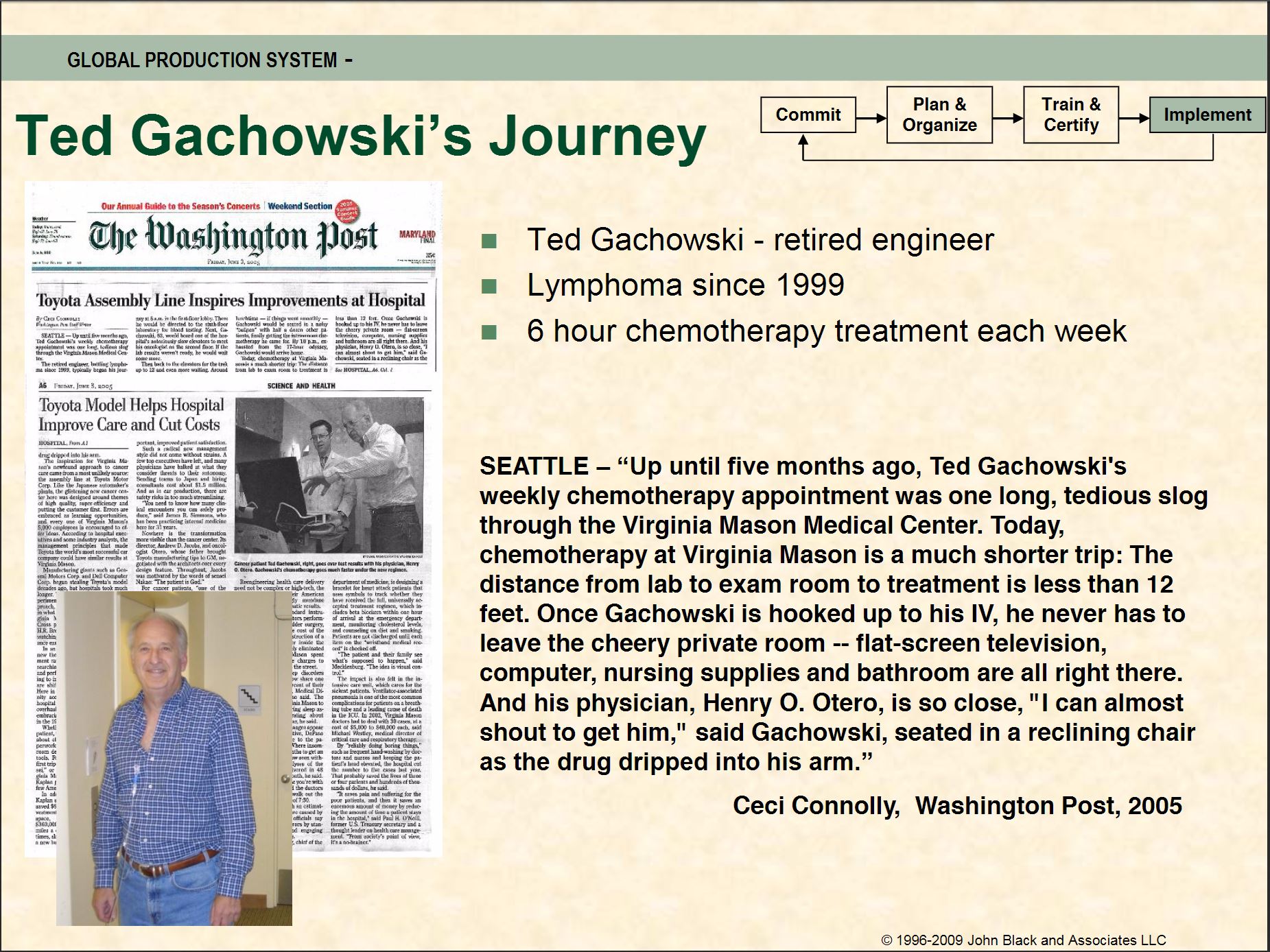

World-class healthcare facilities feel a "survival sense of urgency" throughout the organization, always aware that patients may move on to other care providers offering better care.

In healthcare, your reason for being is quality care. To be a world-class healthcare organization, you must excel at deploying rapid, effective patient care.

Rapid quality care deployment begins with a sense of urgency.

World-class healthcare facilities feel a "survival sense of urgency" throughout the organization, always aware that patients may move on to other care providers offering better care.

This sense of urgency can be directly generated by outside forces. It is a defensive posture. Or, this sense of urgency can also be generated as an attack on a "crisis" whose impact has not yet been felt.

This is urgency generated by internal forces, ordinarily by the organization’s leadership. It is an offensive posture. Internal urgency is what I see from leaders who are ready for change. Leaders who are ready to overhaul their systems and commit to delivering the best care to every patient, every time.

News services must be quality assured, they must meet customer expectations, they must be state of the art, and they must be available immediately. This sense of urgency intensifies improvement and quality assurance efforts. It intensifies focus upon customer expectations. It intensifies efforts to incorporate new technology. And it pulls together all organization’s human capital to get new services and standards of care ready for the very next patient who walks in the door.

The result is that world-class organizations accomplish amazing development speeds for new care technologies and new methods of care delivery. Patients are satisfied—and impressed. Quality care deployment is rapid and effective.

Longer-term benefits are realized. Patient satisfaction increases. Quality improves dramatically. Patient care achieves total quality goals. Patients return again and again because they trust that they are going to get a safe, quality product, fast.

Up next on the blog: building a world-class leadership structure.

This is urgency generated by internal forces, ordinarily by the organization’s leadership. It is an offensive posture. Internal urgency is what I see from leaders who are ready for change. Leaders who are ready to overhaul their systems and commit to delivering the best care to every patient, every time.

News services must be quality assured, they must meet customer expectations, they must be state of the art, and they must be available immediately. This sense of urgency intensifies improvement and quality assurance efforts. It intensifies focus upon customer expectations. It intensifies efforts to incorporate new technology. And it pulls together all organization’s human capital to get new services and standards of care ready for the very next patient who walks in the door.

The result is that world-class organizations accomplish amazing development speeds for new care technologies and new methods of care delivery. Patients are satisfied—and impressed. Quality care deployment is rapid and effective.

Longer-term benefits are realized. Patient satisfaction increases. Quality improves dramatically. Patient care achieves total quality goals. Patients return again and again because they trust that they are going to get a safe, quality product, fast.

Up next on the blog: building a world-class leadership structure.

RSS Feed

RSS Feed