Sakichi Toyoda, founder of the Toyota Group, lived out the spirit of kaizen from childhood. As a teenager, Toyoda led study groups focused on self-improvement for other young people. He also wanted to find a way to improve society on a large scale, through the use of new machine technology.

In the 1890s Toyoda invented a loom that would stop automatically if any of the threads snapped. His invention reduced defects and raised yields, because the loom would not continue using up thread and producing imperfect fabric after a problem occurred. The new loom also enabled a single operator to handle dozens of looms, revolutionizing the textile industry.

In the 1890s Toyoda invented a loom that would stop automatically if any of the threads snapped. His invention reduced defects and raised yields, because the loom would not continue using up thread and producing imperfect fabric after a problem occurred. The new loom also enabled a single operator to handle dozens of looms, revolutionizing the textile industry.

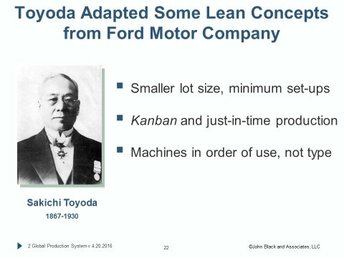

The principle of designing equipment to stop automatically and to immediately call attention to problems is crucial to the Toyota Production System (TPS). The TPS was developed by Toyoda’s son, Kiichiro, and Toyota’s chief process engineer, Taiichi Ohno, who standardized the core of Sakichi’s learnings.

Throughout his time as an engineer at the Toyota Group, Sakichi Toyoda committed himself to rigorous study. Just as we take company tours today, Toyoda traveled to the U.S. and Europe to see how other textile factories organized their production, often after the Toyota Group suffered a setback. Each time a product failed, Toyoda looked for ways to fix the problem. He did not give up on his products. He did not cover up his mistakes. He sought continuous improvement.

The “Toyoda Precepts,” compiled by Toyota Industries management after Sakichi Toyoda’s death:

•Always be faithful to your duties, thereby contributing to the Company and to the overall good.

•Always be studious and creative, striving to stay ahead of the times.

•Always be practical and avoid frivolousness.

•Always strive to build a homelike atmosphere at work that is warm and friendly.

•Always have respect for God and remember to be grateful at all times.

RSS Feed

RSS Feed