Change can be difficult for some, not for others. It can be a mixed bag of attitudes, opinions, resistance, support when you start talking about the Toyota Production System (TPS) among healthcare leaders at all levels. I’ve gotten comments like, “What do you mean TPS, we care for patients, not cars – or at Boeing when we first started, “What do you mean TPS, we build airplanes.”

I’ve been told, “If we bring you in don't use Japanese words or terms, don’t bring in Japanese consultants, don’t start telling us about Toyota, we serve patients, not cars – don't talk about the Toyota Production System.” My comment usually is, “what do you want me to talk about, what do you want?”

I’ve been told, “If we bring you in don't use Japanese words or terms, don’t bring in Japanese consultants, don’t start telling us about Toyota, we serve patients, not cars – don't talk about the Toyota Production System.” My comment usually is, “what do you want me to talk about, what do you want?”

I didn’t hear those words from Dr. Gary Kaplan and Mike Rona, when they brought me in for a one-on-one meeting fifteen years ago in Seattle. What I remember was, “Black, we’ve got a problem around quality and safety issues at Virginia Mason – we care deeply about our patients and it is obvious we can do much better.” They were very open to blowing up their mission statement and vision. Also, they weren’t a least bit arrogant. They said, “John Black, we don’t have a method, a management system, to make happen what your talking about.”

So, what about results? Rona and Kaplan, with coaching from John Black and Associates, led the adaptation of the Toyota Production System into the Virginia Mason Production System (VMPS). With VMPS methods, the team has achieved increases in patient and staff satisfaction, huge reductions in patient wait time and medical errors, stable economic performance.

Rona, now CEO of Rona Consulting, explains the promise of the Toyota Production System best: “What was such an eye opener for us was that this was exactly what we were seeking in healthcare: A zero defect product that exceeded the expectations of its customers, the highest quality, the highest staff satisfaction, the lowest possible cost and reasonable economic performance.”

Lean leadership is an immersive experience, a total transformation. The Toyota Production System is a universal process that translates to all industries and will revolutionize your organization’s ability to harness its human capital.

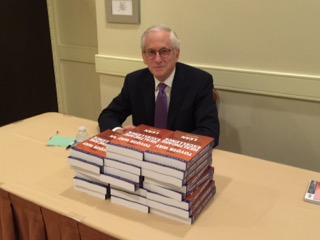

Ready to start your Lean transformation? Check out my book here, or contact me with questions.

So, what about results? Rona and Kaplan, with coaching from John Black and Associates, led the adaptation of the Toyota Production System into the Virginia Mason Production System (VMPS). With VMPS methods, the team has achieved increases in patient and staff satisfaction, huge reductions in patient wait time and medical errors, stable economic performance.

Rona, now CEO of Rona Consulting, explains the promise of the Toyota Production System best: “What was such an eye opener for us was that this was exactly what we were seeking in healthcare: A zero defect product that exceeded the expectations of its customers, the highest quality, the highest staff satisfaction, the lowest possible cost and reasonable economic performance.”

Lean leadership is an immersive experience, a total transformation. The Toyota Production System is a universal process that translates to all industries and will revolutionize your organization’s ability to harness its human capital.

Ready to start your Lean transformation? Check out my book here, or contact me with questions.

RSS Feed

RSS Feed